The welding industry, like most other manufacturing industries, is constantly evolving in the face of new technologies, the most recent of which has been the rise of robotic and automated welding. Automating welding can be an incredibly effective step to take for any welder; however, given that for many it is unchartered territory, they can have a lot of questions when engaging with it for the first time.

If this sounds like you, here are some top tips surrounding automated welding to help get you started.

Learn The Basics

There are a lot of resources out there that will allow you to pick up the basics of automated welding with ease. This can be through different videos, articles or even speaking to a mentor who knows a lot about the craft.

Remember Your Safety

Your and your staff’s safety should always take priority above everything else. Welding, regardless of whether it is manual or automated, can be an incredibly hazardous process. You should ensure that you invest in all the necessary equipment to limit these hazards as much as possible. This includes helmets, gloves, overalls, aprons, safety shoes and skin covers.

Understand the Difference Between Semi-Automated and Fully Automated Welding

It is important to know before you begin practicing or purchasing automated welding machines that automated welding has two sub-categories. These are semi-automated and fully automated.

■ Semi-Automated

This requires an operator to manually load and start the machine. This process is beneficial because whilst it embraces the technological advancements of automated welding, it does not take away the work of a skilled employers in the process. This is the most common sub-category out of the two.

■ Fully Automated

When the process becomes fully automated, the machine takes over everything. The operator would be there to merely observe the process and ensure the machine is working properly, rather than being involved in the welding process. This sub-category is used most commonly in industries that use mass fabrication.

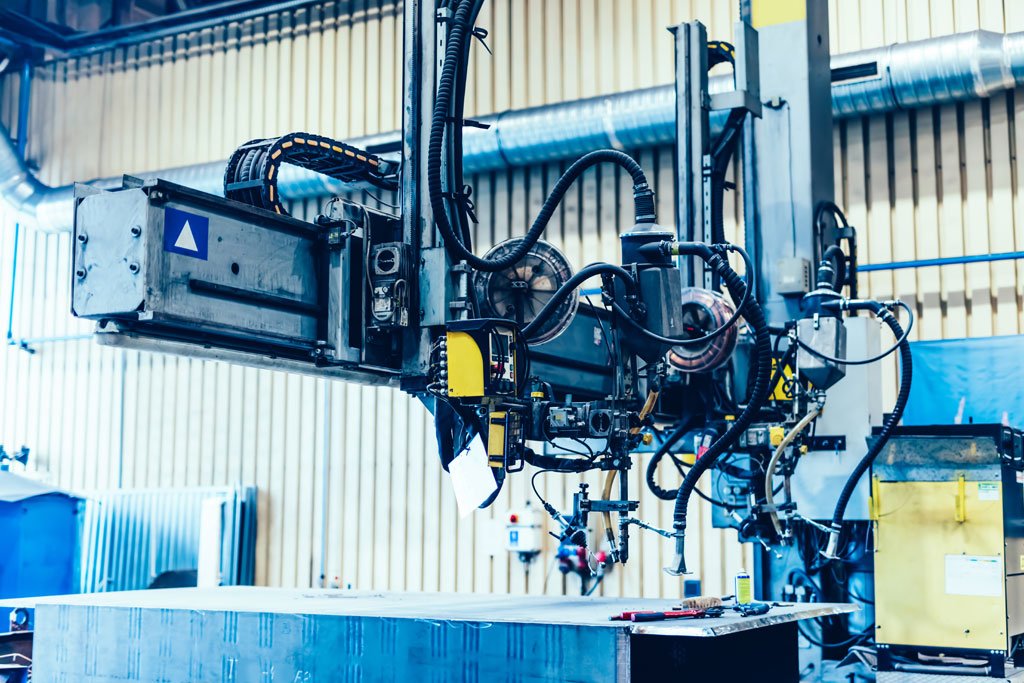

Invest In the Right Machinery

If you are a start-up organization or are investing in automated machinery for the first time, it can potentially be quite a costly experience. You should review the different options available to you to ensure you are purchasing the right welding machines for your needs.

For example, if you are only a small business with modest output, you will not need machines capable of major welding operations. Whereas, if you have a larger output or expect to have a larger output in the future, it makes sense to invest in machinery that can produce that for you.

Also, consider the potential labor costs of the amount you will be producing as this could help in choosing between semi-automated or fully automated machines.

Persevere and Refine Your Skill

Automated welding is incredibly technical and as such can take time to master. You will need to have an in-depth knowledge of the automated process and a basic knowledge of the manual process. That being said, mastering the process can be hugely beneficial for your business, so it is worth persevering with and perfecting the skill.